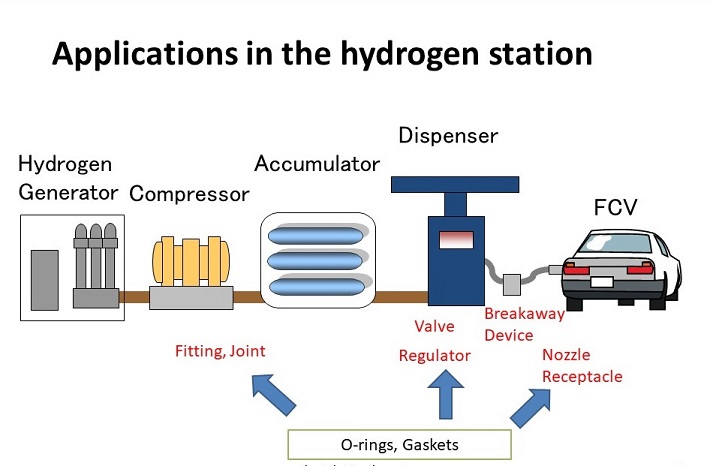

Introduction of devices for hydrogen refueling stations

Vehicles that run by hydrogen as fuel are called fuel cell vehicles (FCVs).

The Hydrogen Refueling Station (HRS) supplies hydrogen to the fuel cell vehicle (FCV).

This time, let us explain about the devices for hydrogen stations.

The peculiar point of the hydrogen station consists in its usage conditions.

There are various pressure and temperature conditions of hydrogen passing through each hydrogen equipment that makes up the hydrogen station, and depending on the devices, the environment is extremely harsh for the O-ring and the rubber sealing.

There are the following four points in the harsh environment.

① The gas is hydrogen

② High pressure

③ There are pressurization / depressurization cycles

④ The temperature range is severe

Let us make introductin of devices and usage conditions for hydrogen refueling stations

・ Hydrogen generation production equipment

(Quoted from Osaka Gas website)

Temperature and pressure are normal temperature and low pressure.

This product is big volume hydrogen generater converted from the city gas.

This device can produce 300Nm3/h.

・ Hydrogen compressor

(Quoted from Kaji Tech Co., Ltd. website)

It is used under high temperature and high pressure.

By gradually increasing the pressure, the temperature rises as it approaches the discharge port.

The pressure is up to 82 MPa and the maximum design temperature is 180 ° C.

In addition, pressure is applied during operation, depressurization is performed when stopped, and there is a pressurization / decompression cycle.

・ Accumulator(Cylinder)

(Quoted from Samtech Co., Ltd. website)

Normally the temperature is ambient temperature and the pressure is high, but there is no big pressure cycle.

・ Hydrogen dispenser

(Quoted from Tokico System Solutions Co., Ltd. website)

With a built-in precooler, the temperature drops to -40C (low temperature).

In addition, 90MPa of hydrogen is filled to the FCV, and when it ends, there is depressurization and it drops to 0MPa (atmospheric pressure).

In particular, at the emergency release coupling (Breakaway device) it is under a very harsh environment for the O-ring because hydrogen temperature is near -40C, continues to flow for about 3 minutes at the time of filling and depressurization is done quickly after filling.

Since each device has different usage conditions, it is necessary to consider the material of the rubber O-rings that seals hydrogen.

Our company have developed O-rings for high pressure hydrogen. Nowadays, it is used in many hydrogen stations in Japan and its usage is spreading.